Yes, many solar panels use polysilicon as a primary material for capturing sunlight.

Understanding Polysilicon

Polysilicon, short for polycrystalline silicon, is a pivotal material in the photovoltaic and electronics industry. Derived from Silicon, it plays an essential role in today’s solar technology. Let’s dive deeper into understanding polysilicon.

What is Polysilicon?

Polysilicon is a high-purity form of silicon, showcasing a multi-crystalline structure. Unlike monocrystalline silicon, which has a single, continuous crystal lattice structure, polysilicon consists of multiple small silicon crystals. It’s the result of melting and solidifying silicon multiple times to enhance its purity.

Production Process of Polysilicon

The production of polysilicon follows several key steps:

- Silicon Mining: Starting with mining quartz, a source of silicon.

- Reduction to Silicon: The quartz is reduced in an electric arc furnace to produce metallurgical-grade silicon.

- Chemical Vapor Deposition (CVD): Using the Siemens process, where silicon is deposited from the gaseous phase onto thin silicon rods.

- Purification: Impurities are reduced through directional solidification, ensuring a higher purity level for photovoltaic applications.

- Casting: The purified silicon is cast into ingots or blocks, which are then sliced into wafers.

The resultant wafers are used in both photovoltaic cells and semiconductor devices. The process requires a significant amount of energy, which makes the environmental footprint of polysilicon a topic of ongoing debate.

Advantages and Disadvantages of Polysilicon

Advantages:

- Cost: Polysilicon solar panels tend to be less expensive to produce than monocrystalline ones.

- Less Waste: The process to produce polysilicon panels leads to less silicon waste compared to their monocrystalline counterparts.

- Tolerance: They perform relatively well in high temperatures, which can be advantageous in warmer climates.

Disadvantages:

- Efficiency: Polysilicon panels have slightly lower efficiency rates compared to monocrystalline panels.

- Space: Due to the lower efficiency, more panels or space might be needed to match the output of fewer monocrystalline panels.

- Aesthetics: They typically have a blueish hue, which might not be as visually appealing to some compared to the black hue of monocrystalline panels.

Understanding the nuances of polysilicon is crucial in the ever-evolving world of renewable energy. As technology progresses, the benefits and challenges of using polysilicon in solar panels may shift, making continuous research and development essential.

Types of Solar Panels

Solar panels, the devices that convert sunlight into electricity, have seen immense advancement over the years. The efficiency, durability, and aesthetics of these panels have improved significantly. Predominantly, there are three major types of solar panels in the market. Let’s explore each of them.

Monocrystalline Solar Panels (Mono-Si)

Monocrystalline solar panels are made of single crystal silicon, making them easily identifiable by their uniform dark look and rounded edges. Here are some key points:

- Efficiency: Among the highest efficiency rates in the industry, often above 20%.

- Longevity: Typically come with a long lifespan, with many manufacturers offering 25+ year warranties.

- Space-Efficient: Their high efficiency means fewer panels are needed for the same electrical output, making them ideal for residential properties where space might be limited.

- Cost: Generally, they are more expensive than polycrystalline panels due to the complex manufacturing process.

Polycrystalline Solar Panels (Poly-Si)

Polycrystalline panels, or multi-crystalline panels, are made from melted raw silicon. They can be recognized by their square-ish cells and a speckled blue or greenish look.

- Efficiency: Typically slightly less efficient than monocrystalline panels, with average efficiency rates ranging between 15% to 17%.

- Cost: Generally less expensive to produce, making them a popular choice for large-scale installations where space isn’t as limited.

- Aesthetics: They might not have the uniform appearance of monocrystalline panels, but advancements are continuously being made to improve their visual appeal.

Thin-Film Solar Panels

Thin-film panels stand out from the traditional silicon solar panels. They are characterized by thin layers of photovoltaic material being placed on a solid substrate or even on flexible bases.

- Flexibility: Some types of thin-film panels are flexible, making them suitable for certain unique applications.

- Weight: They are generally lighter in weight compared to crystalline panels.

- Aesthetics: Can be made semi-transparent, making them an option for windows or other architectural integrations.

- Efficiency: Typically have lower efficiency rates compared to crystalline-based panels, often ranging between 10% to 12%.

- Degradation: Tend to degrade faster than crystalline panels over time.

Choosing the right solar panel depends on the specific needs of the project, budget, and available space. All these types of panels have their strengths and areas of improvement, but collectively, they contribute to a greener planet by harnessing solar energy.

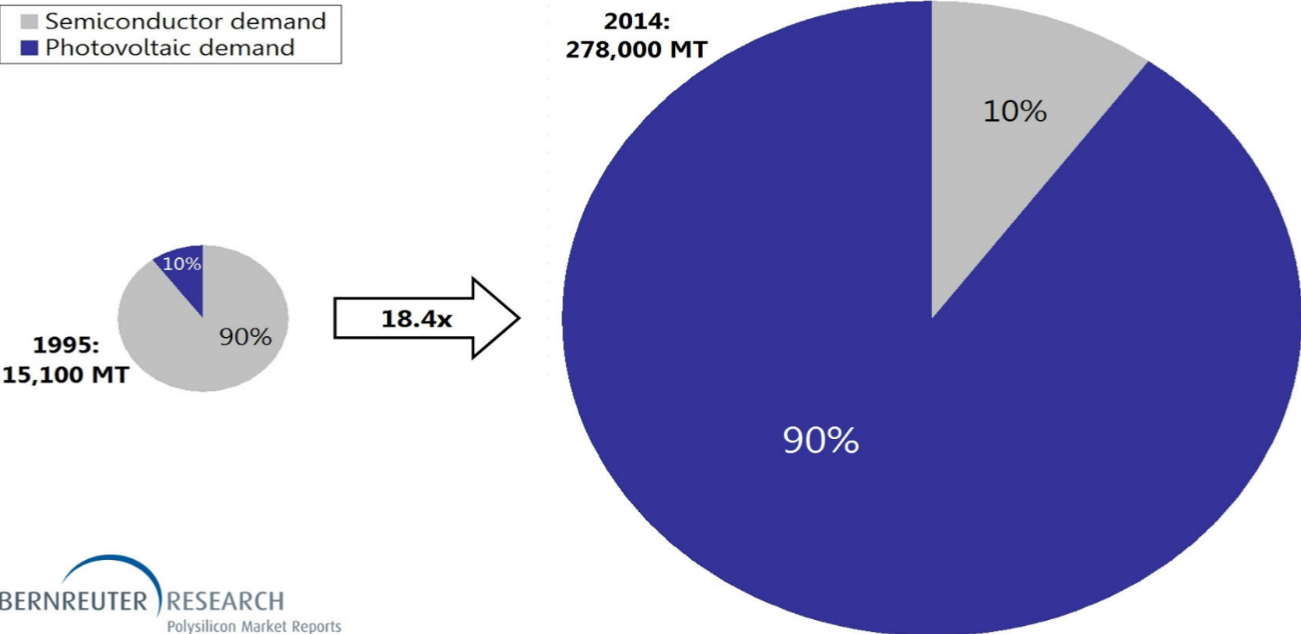

Polysilicon in Photovoltaic Cells

The sun provides an abundant and sustainable source of energy, and harnessing it efficiently requires the right materials. Polysilicon, as a cornerstone in the solar industry, plays a significant role in converting sunlight into electricity. Let’s delve into how polysilicon impacts the performance and evolution of photovoltaic cells.

Role of Polysilicon in Solar Cells

Polysilicon is the primary material used in the manufacture of most solar panels. But what role does it play?

- Material Base: Solar cells need a semiconductor material to absorb sunlight. Polysilicon serves as this semiconductor, absorbing photons and releasing electrons, resulting in an electric current.

- Stability: Polysilicon is inherently stable under sunlight, ensuring that solar panels can function for years without significant degradation.

- Abundance: Silicon, the primary component of polysilicon, is the second most abundant element on Earth, making it a sustainable choice for solar cell manufacturing.

Conversion Efficiency of Polysilicon-Based Cells

Conversion efficiency determines how effectively a solar cell can convert sunlight into electricity.

- Average Efficiency: Polysilicon-based solar cells usually offer efficiency rates between 15% to 20%. While they might not be the highest in the market, continuous research aims to push these numbers further.

- Factors Affecting Efficiency: The efficiency of a polysilicon cell depends on its purity, the quality of manufacturing, and the integration of newer technologies, like PERC (Passivated Emitter Rear Cell) which can enhance the cell’s ability to capture sunlight.

Evolution and Advancements in Polysilicon Technology

Over the decades, there have been significant advancements in the way polysilicon is used in photovoltaic cells.

- From Ribbon to Wafers: Early technologies, like ribbon silicon, were less efficient and more fragile. Modern solar cells use wafer technology, which is more durable and efficient.

- Solar Cell Designs: Newer designs, such as PERC cells, integrate additional layers into the solar cell to capture more sunlight and reduce electron recombination.

- Cost Reductions: Technological advancements have also reduced the cost of producing polysilicon and, consequently, solar panels, making solar energy more accessible to the masses.

The journey of polysilicon in the world of photovoltaics is a testament to human ingenuity. As we continue to innovate, polysilicon’s role may evolve, but its importance in capturing the power of the sun remains undeniable.

Environmental and Economic Aspects

The push for solar energy has often been driven by environmental concerns, aiming for a more sustainable future. However, as with any technology, the production and widespread use of solar panels, especially those made of polysilicon, have both environmental and economic implications. Exploring these aspects helps in making informed decisions on energy policies and investments.

Sustainability of Polysilicon Production

Producing polysilicon requires considerable energy, primarily because of the high temperatures needed in the manufacturing process.

- Energy Consumption: Silicon refinement is energy-intensive. While solar panels can produce clean energy for decades, the initial energy investment is significant.

- Water Use: Large volumes of water are essential for cooling and cleaning in polysilicon production facilities. This can strain local water resources, especially in arid regions.

- Waste Management: The production process results in waste, including silicon tetrachloride, which needs careful handling and disposal to prevent environmental harm.

- Carbon Footprint: Despite being a green technology, the production of polysilicon does have a carbon footprint due to the energy sources used in its manufacture. Over time, however, the clean energy produced by the solar panels can offset this initial carbon investment.

Cost Analysis: Polysilicon vs. Alternative Materials

Polysilicon has been a dominant material in the solar industry, but there are alternatives that also play a role, each with its cost implications.

- Polysilicon Costs: The cost of producing polysilicon-based solar panels has decreased over the years, thanks to technological advancements and economies of scale. This trend makes polysilicon panels more affordable and competitive.

- Alternative Materials: Thin-film technologies, such as CdTe or CIGS, might have a lower upfront material cost compared to polysilicon. However, they often come with a trade-off in efficiency and lifespan.

- Economic Balance: While alternative materials might offer cost savings, the reduced efficiency might require more panels or more space to produce the same amount of energy as polysilicon panels. This can impact the overall economic feasibility of a solar project.

In conclusion, while polysilicon has environmental and economic challenges, its role in driving forward the renewable energy agenda is undeniable. Balancing the environmental concerns with economic realities is crucial in steering the future of solar technology.

Alternative Materials to Polysilicon in Solar Panels

While polysilicon has been the backbone of the solar industry for many years, researchers and companies have been exploring alternative materials to potentially improve efficiency, reduce costs, or tackle specific market niches. These alternatives offer unique properties and advantages, but they also come with their sets of challenges. Let’s explore some of these promising materials.

Cadmium Telluride (CdTe)

Cadmium Telluride (CdTe) is a thin-film solar cell technology that’s gained attention for its potential in solar applications.

- Efficiency: CdTe solar cells have reached efficiencies close to their silicon counterparts, often hovering around the 20% mark in laboratory settings.

- Production Cost: Generally, CdTe solar panels can be cheaper to produce than silicon-based panels.

- Environmental Concerns: Cadmium is a toxic element. Ensuring safe production, use, and disposal of CdTe panels is essential to mitigate environmental risks.

- Market Share: Though still less common than silicon-based panels, CdTe holds the majority share among thin-film technologies, with several large-scale installations worldwide.

Copper Indium Gallium Selenide (CIGS)

CIGS is another thin-film technology that has shown promise.

- Flexible Foundations: CIGS cells can be deposited on flexible substrates, allowing for more diverse applications, including rollable or foldable solar panels.

- Efficiency: CIGS cells have achieved efficiencies surpassing 20% in laboratory conditions, making them competitive with more established technologies.

- Complexity: The multi-element composition makes the production process more intricate, which can influence the production costs and scalability.

- Potential: With further research and development, CIGS has the potential to be a major player in niche markets where flexibility and weight are crucial factors.

Organic Photovoltaic Cells (OPVs)

Organic Photovoltaic Cells (OPVs) utilize organic molecules or polymers to capture sunlight and convert it to electricity.

- Lightweight and Flexible: OPVs can be printed on flexible materials, making them ideal for unique applications such as integration into clothing or fabrics.

- Lower Efficiency: OPVs currently lag behind in efficiency compared to other technologies, often achieving around 10% to 15% in optimal settings.

- Cost-Effective Production: The potential for roll-to-roll printing and other scalable manufacturing processes can make OPVs a cost-effective solution for specific applications.

- Degradation: Organic materials can degrade faster than inorganic alternatives, which can impact the longevity of OPVs.

In the grand scheme of things, while polysilicon remains dominant, these alternative materials open new doors for innovation in the solar industry, each carving out its niche based on unique strengths and challenges.